The robotics industry has long been fragmented. Heck, Bill Gates mentioned it back in 2008. Progress has been made, sure, but a lack of common standards and platforms, as well as programming complexity, remain major hurdles for the industry.

A tour of READY Robotics’ headquarters in Columbus, Ohio, however, showcases just the opposite. The robotics playground features a variety of robots that take their orders from one universal control system. It’s a glimpse into the future the company is hoping to help create. READY Robotics has been working since 2016 to ensure fragmentation and robotics are no longer associated with one another.

Today, READY Robotics took another step in that journey with the release of Forge/OS 5. The operating system (OS) controls robots from all the major brands. Benjamin Gibbs, co-founder and CEO of READY Robotics, wants Forge/OS to do for robots what Windows did for PCs and Android did for smartphones. “This is how we go from hundreds of thousands of robots sold to millions,” he said.

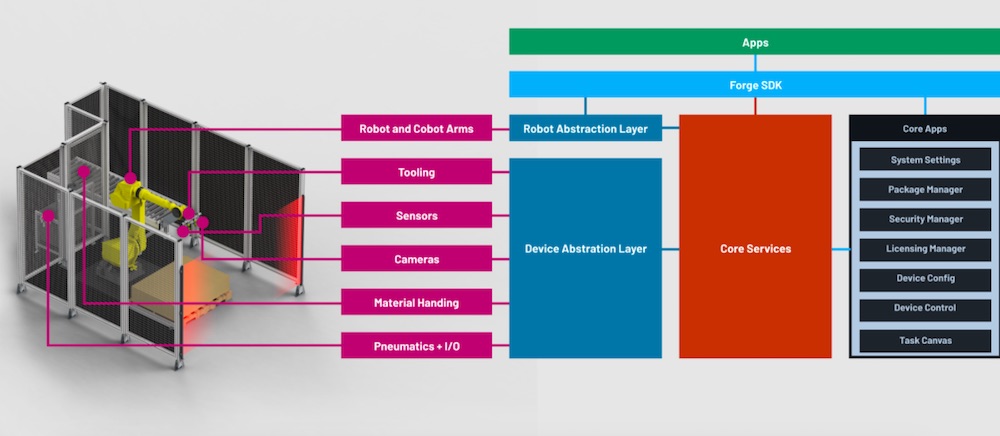

Forge/OS 5 is already compatible with 250-plus robots and counting. This includes collaborative robots (cobots) and traditional industrial robots, with support for SCARA robots coming soon. The OS also supports a growing list of accessories, including cameras, force sensors, grippers and much more.

Forge/OS 5 is built on Linux, C++, and Qt 5.15. One of the main goals is to reduce complexity for customers who use multiple brands of robots and peripherals. To do so, Forge/OS 5 abstracts brand-specific robot programming languages into a no-code programming app called Task Canvas. The system uses blocks of code that are organized into flow charts depending on the application at hand.

Watch the Forge/OS 5 launch event

READY Robotics said users don’t need a PhD in robotics to learn Task Canvas. Each block of programming has customizable parameters based on the type of action. Those parameters can be changed by the user to control the robot or any devices or peripherals connected to Forge/OS. Because the OS is an open platform, third-party developers can build their own apps or Task Canvas blocks if needed.

READY Robotics has partnered with about 50 companies at the moment. But expect many more to be on the way. Josh Seabloom, vice president of engineering at READY Robotics, said Forge/OS 5 has been built to facilitate third-party development. A Forge SDK beta will open in June 2021.

READY Robotics built a robotic simulator on top of ForgeOS 5 with Unity’s gaming engine. The simulator lets you program a variety of robots in physics-based environments. Kel Guerin, co-founder and CIO of READY Robotics, demoed pick and place and machine tending simulations. He said that because the simulator uses the actual ForgeOS interface to program the simulated robots, anything learned in the virtual environment will “directly translate into a real production work cell once you’re working with a physical system.”

“Until now, there hasn’t been a good channel for developers to build the apps that have the power to ignite the explosive spread of automation,” said Juan Aparicio, VP of product at READY Robotics. “We are incredibly excited to enable the brightest builders in the world, regardless of background, to dream up and create products that will impact automation the way they have impacted other industries. Creating a true developer ecosystem for automation has the potential to usher in a new golden age of automation.”

Aparicio joined the company in March 2021 after spending 10-plus years at Siemens, leading its advanced manufacturing automation team. Aparicio also spoke in our RoboBusiness Direct Series about “Robotics at the Edge: Flexible Manufacturing, Intelligent Machines, and Edge Robotics.” You can watch the session on demand here.

He was also recently on The Robot Report Podcast. We discussed why ease of use has been overlooked in the robotics industry, how easy programming robots will become and other innovations that can further robotics adoption. He also shared a great story about one of the most difficult times he’s had programming a robot. You can listen to that discussion below starting at the 38:16 mark.

Leave a Reply

You must be logged in to post a comment.